Lasermet’s Safety Logic Plus is a simplified but cost-effective and secure concept in which the logic configuration required for a safety Interlock® system is hardwired in a single logic enclosure. The system makes use of modules that accept input from all Interlock® switches.

This enclosure houses the safety Interlock® logic functions. When all of the safe conditions, including self-checking, are met, it is programmed to arm the laser via the Lasermet Interlock® Controller.

Safety Logic Plus

Safety Logic Plus

The diagram above illustrates the typical complexity and subsequent simplification of circuitry only in pictorial form. Some of the complex diagram’s 32 connections are wired together so that each diagram has the same number of inputs and outputs.

Customers can design and build complex safety Interlock® systems while virtually eliminating obsolescence because the Safety Logic Plus has a life expectancy of 30 years or more. The streamlined on-site installation techniques reduce installation time and costs while also simplifying testing and fault finding procedures.

The Need for Safety Logic Plus

Standard simple Interlock® systems consist of a series of door contacts connected in series to form a safety loop. This information is sent back to Lasermet’s Interlock® controller.

However, with more powerful lasers and a greater number of them, it is even more critical that laser safety interlocks be installed at a low cost and that their logic be easily understood, maintained, and updated, especially when there are new lasers or changes to the facility.

To meet this need, Lasermet developed the Safety Logic Plus concept, which is a non-processor-based fail-safe logic system that integrates all of the logical functions of the Interlock® system into a single enclosure. All that is required is to connect each door contact and other control to Safety Logic Plus via individual cables. The system’s logic function is carried out by interconnecting the internal logic modules in accordance with the logic diagram. A competent electrician can wire this.

- Installation, maintenance and testing is straightforward

- No specialist PLC training is required

- The design enables easy and fast fault finding

- Logic changes are done within the enclosure

INCREASED COMPLEXITY

Modern Interlock® systems have a tendency to be configurable in order to provide multiple modes of operation and varying coverage areas. Implementing such systems with point-to-point wiring between the various door contacts and controls within a building presents significant challenges for installation, testing, and fault-finding, raising installation and maintenance costs.

SIMPLICITY AND SAFETY THROUGH HARD-WIRED LOGIC

The wiring system can be simplified by using AND and OR gate modules to implement the basic logic. The components are all basic electrical components like hard wired jumper type connectors, relays, and LEDs.

SAFETY THROUGH DESIGN

To provide the logic function, the relay-based logic gates are connected using jumper leads. Because each module has its own LED, it is simple to inspect. Every module has a cross checking function applied to it, so that if it fails or there is no input to it, the laser will not arm. Throughout the system, double safety circuits are used.

- It is a fail-safe system

- It uses dual channels

- It has full cross checking of all circuits

- The laser will not arm until all circuits are checked on both channels and all conditions are satisfied including self-checking.

ELIMINATE OBSOLESCENCE

This logic system eliminates the obsolescence issues that have already emerged with PLC-based systems, which rely on interface standards and operating systems that rapidly become obsolete. It does not require any programming languages, software, or a computer with an operating system, and thus is unlikely to become obsolete.

Through its fail-safe design, Safety Logic Plus eliminates a variety of issues. All wires are fed directly back to the enclosure where the logical functions are determined from all remote door locks or switches.

- No software

- No Programmable Logic Control

- No operating system

- No specialist training

SIMPLE CUSTOM DESIGN

The design is such that any competent engineer who can follow the wiring diagram is able to check, test, modify or replace any modules or wiring. He does not require any diagnostic software, programming skills, any specific operating systems or other potentially obsolete test equipment. The system can be adapted, upgraded and modified at one point within Safety Logic Plus.

- All safety switches are connected to the enclosure.

- The enclosure houses all logic functions.

- All logic functions are performed using modules.

CALM for Safety Logic Plus Systems

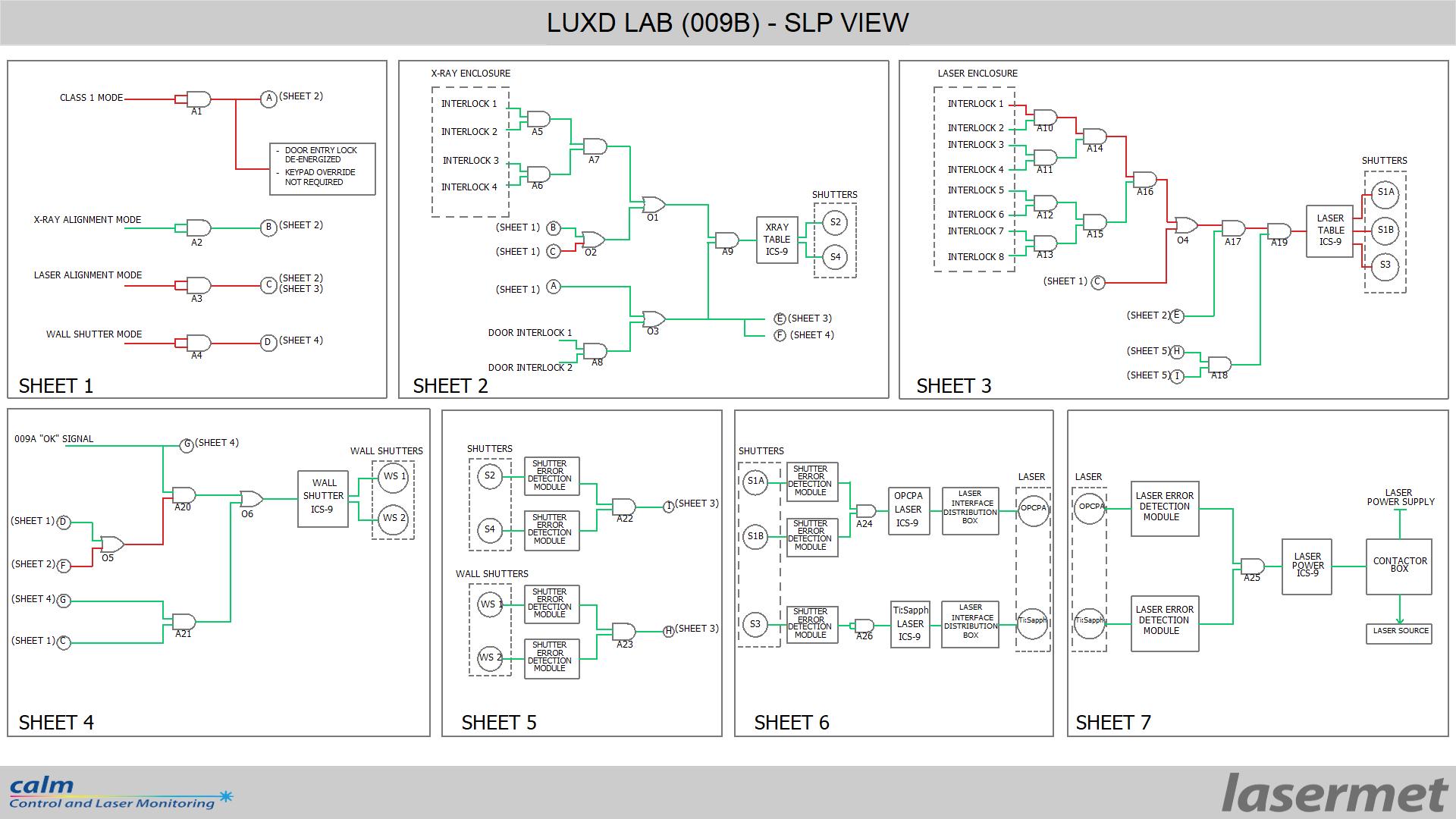

With the CALM System, Safety Logic Plus circuits are simplified to achieve complex system functionality while easily displaying system status at a glance.

With the SLP View on the CALM monitor, users can view traceable logic circuits making fault-finding a breeze for large systems. The possibilities are endless – each CALM display is made custom for each unique Safety Logic Plus system.

Trace a fault in the system by following the logic diagram. In this example, we can trace back the fault to Interlock 1 on the laser enclosure.

The Lasermet Solution

- Wiring at a complex site

- Altering existing, conventional wiring system installations can be difficult, time consuming, and thus costly. As a result, Safety Logic Plus is a cost-effective solution.

- Identifying flaws

- Because of the design, faults are frequently identified almost immediately.

- Cable identification failure

- This frequently happens to cables during installation or during the system’s operational life when maintenance or changes are made to the building or the wiring itself. Safety Logic Plus makes it easier to identify unmarked installed cables.

- Elimination of software bugs associated with any software used, particularly Programmable Logic Controllers. It cannot become obsolete because there is no software. This includes the software itself, the type of program (including language), and the operating system that it runs on. Any maintenance or changes are simple to implement for the equipment’s expected lifetime of more than 30 years.