The purpose of the LS200 Laser Safety Shutter is to shield users from unintentional exposure to potentially dangerous laser beams.

The laser beam travels through the shutter in clear air when it is open. When the shutter is closed, the incoming laser beam is diverted to a suitable beam dump that needs to be installed via a different port.

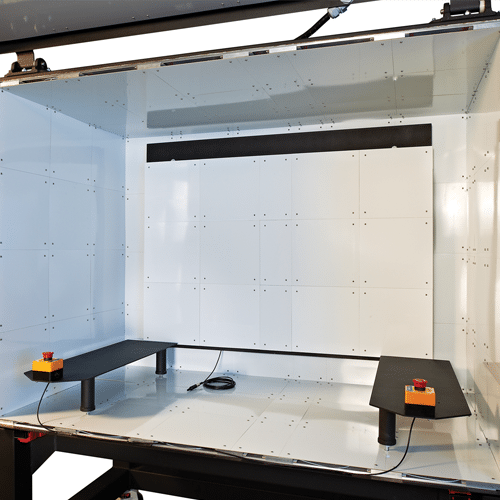

The LS-200 shutter, a power/communications cable, and fastening nuts make up the equipment. Although it is a separate item, the air-cooled beam dump and shutter can be supplied together as a complete set. When using a mirror blade and more powerful lasers, users might want to consider using a different beam dump with a larger capacity.

The shutter uses a gravity close blade and force-disconnect proving contacts and is designed to form part of a high-integrity safety system.

A SIL3 dual version is also available which, when correctly wired with the Lasermet Interlock® Controller System can provide a safety Interlock® which meets Safety Integrity Level 3 to EN 61508 and ISO 13849-1 Performance Level ‘e’.

The shutter is intended to be a component of a high-integrity safety system. It has a gravity close blade and force-disconnect proving contacts.

There is also a SIL3 dual version that can provide a safety Interlock® that satisfies ISO 13849-1 Performance Level “e” and Safety Integrity Level 3 to EN 61508 when properly wired with the Lasermet Interlock® Controller System.

The aperture of the shutter is Ø50mm (1.97 inch).

LS-200 Standard and LS-200 SIL 24 Laser Shutters

CONTROL OPTIONS

The shutter is usually controlled and powered by a Lasermet Interlock® controller when all safety interlocks have been closed. If the Interlock® is tripped out the shutter closes immediately. It cannot be opened until the Interlock® system is re-armed. There are three options in wiring the shutter.

- Arming the Interlock® system enables the operation of the shutter. The shutter can then be opened or closed using the buttons on top of the shutter.

- In addition to option 1 above, the shutter may be remotely opened or closed by external controls such as Lasermet’s LS-20 LS-RS units.

- Arming the Interlock® opens the shutter immediately.

BLADE OPTIONS AND BLADE CLEANLINESS

Blade options include:- stainless steel, copper, ceramic and coated glass. Cleanliness of the blade is important. A perfectly clean blade will successfully divert a beam. It is essential that the blade is kept clean to avoid excessive heat absorption as this can lead to ablation of stainless steel blades.

POWER RATINGS

The standard LS-200 shutter using a stainless steel blade is rated to sustain a 100W laser that has a beam diameter of 10mm (0.39 inch). This is suitable for use with the air cooled beam dump shown. Users must ensure the external beam dump can absorb and dissipate the laser power. The PEL ratings are shown below.

LASER BLOCKING SPECIFICATION

POWER DENSITY

Typically the LS-200 standard shutter using a stainless steel blade can handle 100W based on a 10mm (0.39 inch) beam diameter.

The PEL ratings below are for a standard stainless steel blade.

| IRRADIATED AREA | PEL (T2) 100 S | PEL (T1) 10000 S |

| 4 mm² | 5 MW/m² | 5 MW/m² |

| 20 mm² | 2.5 MW/m² | 2.5 MW/m² |

| 80 mm² | 1.3 MW/m² | 1.3 MW/m² |